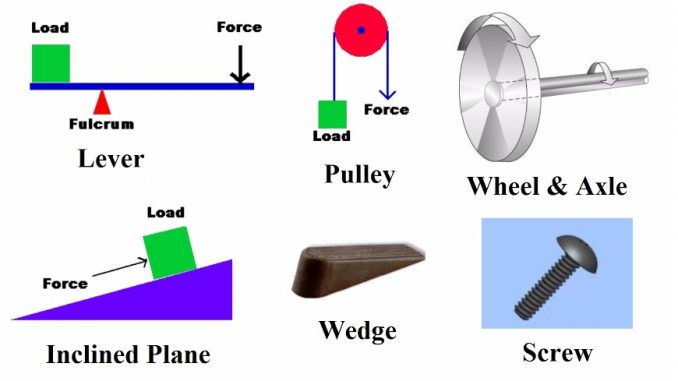

There are six types of simple machine

- Lever

- Pulley

- Wheel and axle

- Inclined plane

- Wedge

- Screw

Lever

- A lever is a rigid bar (straight or bent) capable of turning about a fixed point about an axis called fulcrum. Some examples are: See saw, nut cracker, scissors, wheel barrow etc.

- The distance between the fulcrum and the load is called the load arm (load distance) and the distance between the effort and the fulcrum is called the effort arm (effort distance) of the lever.

- Lever works on the principle of moment. For equilibrium, the moment of the effort arm about the fulcrum must be equal and opposite to the moment of load about it.

Load × Load arm = Effort × Effort arm

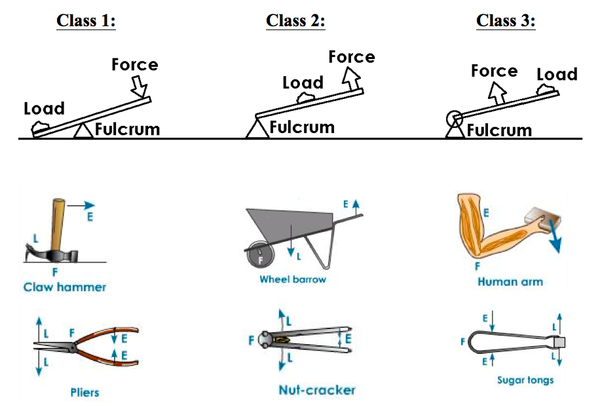

- According to the position of fulcrum and points of application of the effort and the load, levers are classified into 3 types:

First Class lever:

- Fulcrum lies in between the load and effort.

- e. g. Crow bar, scissors, pliers etc.

- According to the position of effort arm, the MA can be equal to 1, more than 1 or less than 1.

Second Class lever:

- Load lies in between the fulcrum and effort.

- e. g. Nut cracker, wheel barrow, bottle opener etc.

- In this lever, the effort arm is always longer than load arm.

- Therefore, MA is always greater than 1 and hence multiplies the force applied.

Third Class lever:

- Effort lies in between the load and fulcrum.

- e. g. Forceps, knife, fire tongs, fishing rods etc.

- In this lever, the effort arm is always smaller than the load arm.

- Therefore, MA is always less than 1 and hence accelerates the work.

Pulley:

- A pulley is a circular disc (generally wooden or metallic) having a groove in its edge over which a rope or string passes and capable of rotating freely about a fixed point called axis or axle.

- The ends of the axle of the pulley are supported on a frame called the block.

- The block of the pulley is either fixed or free to move.

- The block is fixed in a fixed pulley whereas in a movable pulley, the block and pulley along with the load move together.

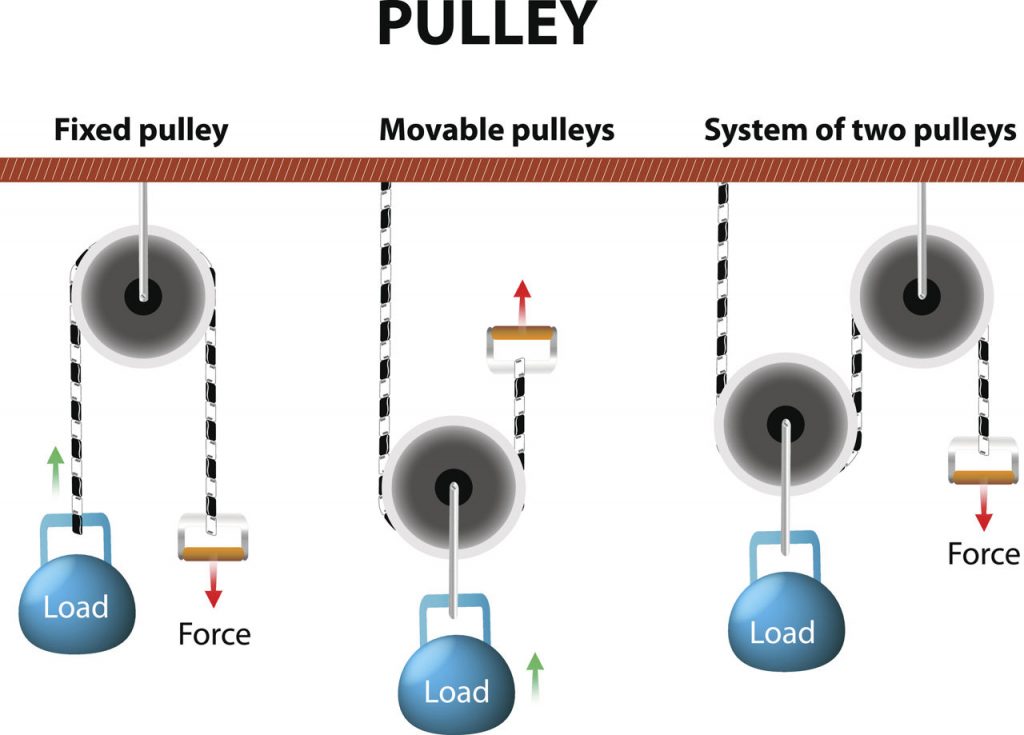

Types of pulley

1. Single fixed pulley

2. Single movable pulley

3. Combined pulley

1. Single Fixed pulley

- This system consists of a single pulley which is fixed and does not move up and down but rotates about its axis.

- A rope or string passes through the groove. At one end of rope, the load is attached and at another end the effort is applied.

- The effort distance and load distance are always equal; hence this pulley does not magnify our effort but helps us by changing the direction of effort.

- In practice, some friction is always present; therefore, the input work is always greater than output work. Hence, MA is always less than 1.

For a single fixed pulley,

MA = Load/effort

VR = effort distance/Load distance (VR=1)

Efficiency = (MA/VR) × 100%

2. Single movable pulley

- It consists of a single pulley which moves up and down along with the load.

- One end of the pulley is tied with rigid support and at another end the effort is applied to lift the load. The load is attached with the hook provided in the pulley system.

- This type of pulley does not change the direction of our effort but helps us by magnifying the effort applied.

- The effort distance is double the load distance and therefore, the velocity ratio is always 2.

For this system,

MA = load/Effort

VR = Effort distance / Load distance (VR=2)

Efficiency = (MA/VR) ×100%

3. Combined pulley (Block and Tackle Pulley)

- In this system, there are two sets of pulleys used.

- It consists of two blocks, one of which is fixed to a rigid support and the other is movable.

- Each block may have an equal number of pulleys, or the upper block may contain one more.

- This type of pulleys is also known as Block and Tackle.

- The ‘tackle’ is the rope or chain connecting the two blocks and passing round all the pulleys. The effort is applied at the free end of the rope.

- This type of pulley changes the direction of our effort as well as magnifies our effort.

For Combined pulley system,

MA = Load/Effort

VR = Effort distance/ Load distance

VR = No. of pulley used in the system or no. of rope segments used to support the load.

Efficiency = (MA/VR) × 100%

Wheel and Axle:

- A wheel and axle is a machine which consists of two co-axial cylinders of different radii.

- The bigger cylinder with greater radius is known as wheel and the smaller cylinder with fewer radius is known as axle.

- Wheel and axle both are without grooves at the circumference. When the wheel is rotated, the axle also rotates.

- The load is raised at the axle whereas the effort is applied to the wheel to overcome the load.

- In a wheel and axle, the support acts as fulcrum. At one end of rope, the load is tied and at another end of rope, the effort is applied.

- When the effort is applied on the rope continuously, the load gets raised continuously. i. e. as long as the effort is applied, the load keeps on moving.

- Therefore, wheel and axle is also known as continuous lever.

- Wheel and axle is used for lifting heavy load by small effort.

- Some examples of wheel and axle are: Screw driver, door knob, steering of vehicle, sewing machine etc.

MA = Load/Effort

VR = Effort distance /Load distance

= Radius of wheel/ radius of axle

Efficiency = (MA/VR) ×100%

Inclined Plane:

- An inclined plane is a rigid and flat surface inclined at an angle to the horizontal surface.

- By the help of inclined plane, heavy loads can be lifted with the help of less effort. It is used to raise a body or load through some desired height.

- Some examples are; Winding roads on the hills, staircase, wooden plank used to lift the goods in truck etc.

MA = Load/Effort

VR = Effort distance/Load distance

= Length of the plane/Height of the plane

Efficiency = (MA/VR) × 100%

Input work = Effort × length of the plane

Output work= Load × height of plane

Wedge:

- A wedge is a triangular tool often made up of metal, wood, stone or plastic.

- It is thick on one end and tapers to a thin or sharp edge on the other end.

- Wedges work by changing direction and force applied to it. Pushing the wedge in one direction creates a force in a sideways direction.

- A wedge may be attached to a handle to make it easier to use.

- It is usually used for splitting, lifting, or tightening. e.g knife, axe etc.

- The mechanical advantage of a wedge is higher when the wedge is longer with a thinner tip.

Screw:

- Screw is a usually circular cylindrical structure with a continuous helical rib which is used either as a fastener or as a force and motion modifier.

- A screw is simply an inclined plane around a cylinder.

- More importantly, it is a cylindrical shaft that has ridges winding around it, called threads.

- Screws are very useful for holding things together and it can pull or push an object together.

- They can be used to lift very heavy objects and tighten things too.

- Bolts, screws, bottle tops, guitar tuners, light bulbs, cork openers are few examples of screw.

Moment

- The turning effect produced by a force about a fulcrum on a body is known as the moment of force.

- The turning effect of a force depends on two factors:

- The magnitude of the force (effort applied)

- The perpendicular distance from the point of application of force to the fulcrum

- The moment of a force is measured as the product of force and perpendicular distance from the point of force to the axis of rotation (moment arm).

- Thus, Moment of force = force × moment arm.

S.I. unit of force is Nm .

Principle of moment

- It states that “when a body is at equilibrium condition ,the total sum of clockwise moment is equal to the total sum of anticlockwise moment about a given point ‘’

i. e. sum of clockwise moment = sum of anticlockwise moment

effort × effort arm = load × load arm